Safeguard against victimization by preemptively thwarting thieves attempting to pilfer trailers, motorcycles, ladders, and equipment from your premises. Utilize locks impervious to bolt cutters and other shed security products to fortify your defenses.

Overcoming the Threat of Bolt Cutters

Halting the endeavors of thieves necessitates diligence. According to Justin Matuszek of Master Lock, “A determined thief armed with an angle grinder and sufficient time can breach nearly any lock. However, more commonly, thieves wield bolt cutters, aiming for expeditious theft.”

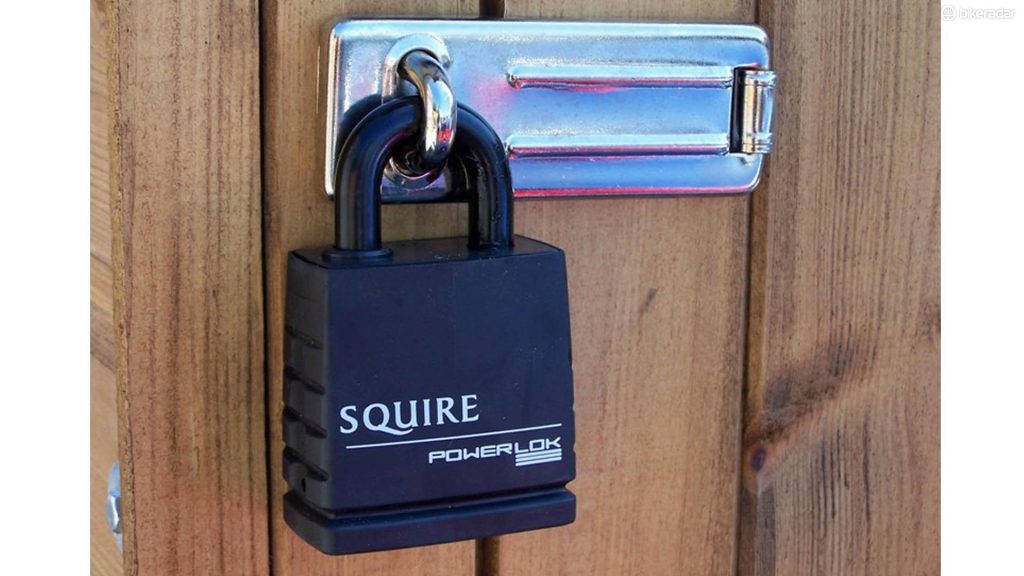

Matuszek emphasizes that a lock’s resistance to bolt cutters is influenced by the thickness of its shackle and the degree of exposure. Moreover, the type of locking mechanism employed plays a pivotal role in the susceptibility of a lock to picking. Both the Master Lock Magnum keyed padlock and the Master Lock ProSeries Combination Lock demonstrate resilience against bolt cutters.

Enhanced Security with Ball-Bearing Locking Mechanisms

Padlocks featuring ball-bearing locking mechanisms exhibit heightened resistance to prying attempts. Those constructed from boron, being 50 percent harder than hardened steel, prove more formidable in deterring thieves.

Thwarting Thieves through Welded Eye Bolts

Integrate a welded eye bolt into the framework of your garage by securing it through one of the studs. Employ a chain or cable lock to fasten your ladder or boat to the eye bolt, thereby impeding swift theft attempts and deterring potential wrongdoers.

Optimal Chain Design: Hexagonal or Square Links

A robust, hardened steel chain featuring hexagonal links serves as an effective deterrent against the majority of thieves armed with bolt cutters. The geometric design of hexagonal links (or square or trapezoidal) renders it impractical for bolt cutters to gain a sufficient grip.

While chains available by the foot at local hardware stores excel in tasks such as lifting and towing, they often fall short in terms of theft resistance. Even those of substantial thickness typically utilize round links, and if a hardware store clerk can effortlessly cut through the chain, so can a potential thief.

Vulnerabilities of Inexpensive Chains

Inexpensive chains, cables, and padlocks, up to 3/8 inch thick, succumb easily to a $20 bolt cutter. A Grade-43, 3/8-inch high-test, hot-dipped, galvanized zinc link from a home center was severed in a mere five seconds using a standard 24-inch bolt cutter. Chains of this caliber are unlikely to impede thieves and may pose minimal resistance.

Swift Erosion of Low-Quality Cable

A 24-inch bolt cutter can swiftly sever a 5/8-inch vinyl-coated, flexible, braided, steel cable in under 60 seconds. Though the cable requires a bit more time to cut compared to a solid chain, it lacks the clean severance of its sturdier counterpart.

Bike Cuffs for Enhanced Security

An invaluable suggestion from a retired police officer for safeguarding bicycles involves using a pair of handcuffs. This method allows for the secure locking of both the bicycle and its wheels. A single set of cuffs can accommodate two bikes or be employed to physically restrain a bike frame to various anchor points. Handcuff keys are compact and easily portable, and standard cuffs crafted from durable steel are cost-comparable to bulky bike locks.

Master Lock Street Cuffs Lock, highly acclaimed by users, incorporate pivoting links to thwart thieves attempting leverage with a bolt cutter. Their compact size enables convenient pocket carriage.

Enhancing Security through Audible Deterrents

Deter potential threats to valuable assets such as motorcycles and trailers by incorporating audible alarms into cable locks and ensuring the overall security of your garage. Additionally, deploy alarms on gate latches, shed doors, and garage entrances to fortify your perimeter.

A plethora of alarm options are available, including movement sensors that can be mounted on doors and strategically angled to cover windows. Numerous do-it-yourself (DIY) alarm systems exist, ranging from battery-operated to ultrasonic (key fob) and solar-operated variants. Notably, the FJM Security SX-776 Cable Lock Alarm emits a piercing shriek upon the detection of a cut in its 24-inch retractable cable.

Integration of Eye Bolts into Concrete Projects

When undertaking concrete projects such as new steps, driveways, patios, or footings, consider embedding an eye bolt in the concrete for added security. Position the eye loop to avoid interference with daily foot or vehicle traffic, opting for a welded loop for durability. This strategic placement serves as a secure anchor point for attaching trailers, generators, motorcycles, grills, bikes, and other valuable items. Stainless steel and galvanized eye bolts are readily available at home centers and marine suppliers, often used in dock construction. For those averse to permanent concrete piers, screw-in ground anchoring products offer a viable alternative.

Enhancing Shed Security with Secure Fasteners

While a locked shed may appear secure, resourceful thieves can circumvent standard locks by using a screwdriver to dismantle hinges and other hardware featuring exposed screw heads. Thwart such attempts by employing Allen-head, Torx-head, or hex-head cap screws instead of conventional Phillips-head screws. Alternatively, tamper-proof security screws, requiring specialized removal tools, can be procured to further enhance security. It is essential to acquire the corresponding special bits or tools for effective implementation.

Securing Shed Door Hinges: Two Approaches

Typically, shed doors swing outward, rendering hinge pins vulnerable from the exterior. Exploiting this vulnerability, a thief can effortlessly dislodge the pins and detach the door. To counteract this method of unauthorized entry, consider two effective strategies. Firstly, invest in security hinges equipped with tamper-proof pins and a locking tab to fortify your shed’s entrance. Alternatively, retrofit an existing hinge by removing the center screws on both sides. Insert a finish screw through one side, allowing it to protrude approximately 1/4 inch. Modify the receiving hole on the opposite side so that, when the door is closed, the finish screw head engages the corresponding hinge. This adjustment ensures that even if the hinge pin is removed, the door remains securely attached.

Enhancing Security for Alloy Wheels

The prevalence of late-model vehicles featuring alloy wheels and low-profile tires, characterized by a reduced distance between the rim and tread, has resulted in an increase in bent alloy wheels. With factory replacements costing over $300 each, vehicle owners often turn to used wheels from recycling yards, creating a shortage of available used alloy wheels. Consequently, the surge in demand has led to a corresponding rise in alloy wheel theft, with reports indicating that thieves can strip all four wheels from a vehicle in approximately five minutes.

To counteract this trend, vehicle owners with alloy wheels are advised to install locking lug nuts as a deterrent against theft. While acknowledging that locking lug nuts are not infallible, their specialized socket requirement adds a layer of complexity, slowing down potential thieves. As a precautionary measure, replace one standard lug nut on each wheel with a locking nut. For enhanced security, the installation of two locking nuts per wheel is recommended.

Enhancing Trailer Security Measures

Frustrate trailer thieves by steering clear of conventional coupler “latch locks,” which prove easily penetrable with even the most modest bolt cutters, allowing perpetrators to abscond with your trailer in mere moments. For a robust defense, opt for a coupler lock that poses a genuine challenge to would-be thieves. This entails inserting the ball into the coupler and sliding on the U-bracket. Unless there is ample time to dismantle the entire coupler and replace it, this approach effectively thwarts the majority of theft attempts.

Furthermore, ensuring the correct and secure hitching of your trailer in the first instance is paramount.

Enhancing Security for High-Value Trailers

For trailers of significant value, an additional layer of protection is recommended through the utilization of a “boot”-style lock in conjunction with the coupler lock. Various styles are available, but a notable choice is a model that serves dual purposes, functioning not only as a secure wheel lock but also as a wheel chock to prevent unintended trailer movement. Simply slide the lock onto the wheel and engage the lock cylinder to fortify the trailer’s overall security.