Learn how to troubleshoot and repair various components of your toilet, including flappers, fill valves, flush valves, and handles.

Introduction

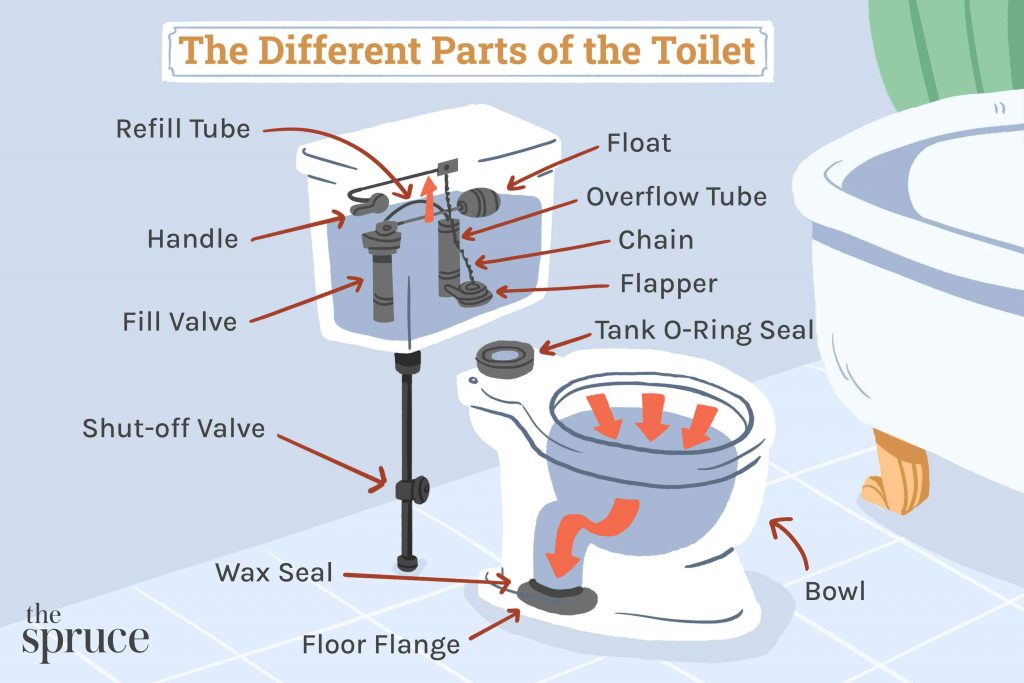

Toilets are equipped with moving parts, and over time, these components can wear out or malfunction. If you’re dealing with a running toilet that won’t stop, it’s worthwhile to address or replace key toilet parts. In this guide, we provide insights into repairing or replacing essential toilet tank components. While the interior of your toilet and its parts may not appear pristine, with surfaces marked by scum, water stains, and corrosion, rest assured that the water within is as clean as what flows from your faucets.

Tools Required:

- 4-in-1 screwdriver

- Adjustable wrench

- Bucket

- Locking pliers

- Pliers

- Shop vacuum

- Tape measure

Materials Required:

- Fill valve

- Flapper

- Toilet handle and retaining nut

- Valve washer

Identifying the issue with a running toilet is typically straightforward. A toilet may run continuously if the fill valve, responsible for allowing water into the tank, fails to close entirely. On the other hand, intermittent running may occur when the flapper valve opens slightly for a few minutes. In both scenarios, it is essential to diagnose why the fill valve is not halting the water flow and whether any damaged toilet parts require attention.

Step 1: Look for Leaks

Examine the toilet for leaks around the tank bolts or toilet flush valve. If leaks are present, it is likely necessary to remove the toilet tank from the bowl for the replacement of tank bolts, rubber washers, and gaskets on the flush valve. Tighten the locknut if leaks are observed around the fill valve. Cracks in the tank can also be a source of leaks, requiring the installation of a new toilet for a reliable solution.

Step 2: If No Leaks Are Found, Lift Off the Tank Cover

The main components of a toilet tank are the flush valve, responsible for water release during flushing, and the fill valve, facilitating tank refilling after flushing. When a toilet runs continuously or intermittently, one of these valves is usually the culprit. Examine the overflow tube to determine which valve is causing the issue. If water overflows into the tube, there’s likely an issue with the toilet fill valve. If the water level is below the tube’s top, the flush valve may be leaking, allowing water to trickle into the bowl and preventing the fill valve from closing completely.

Step 3: Adjust the Float

If your flapper valve features a ball that floats at the end of a rod, gently lift the rod and listen for the water shutting off. Adjusting the float may help stop the continuous running. To achieve this, gently bend the float arm downward to apply extra pressure on the toilet valve. For floats without an arm, refer to Step 14, “Adjust the Float” below. Flush the toilet to assess if the adjustment resolves the issue. Some fill toilet valves have a float adjustment screw on top (refer to the image below). If there is no adjustment screw, bend the float arm. For Fluidmaster-style fill valves, ensure proper adjustment without the need to empty the tank.

Step 4: Take Off the Fill Valve Cap

Remove the fill valve cap by pressing down and turning counterclockwise for this specific type of toilet valve. If dealing with other valve types, remove screws as necessary.

Step 5: Flush the Valve with Water

Cover the flapper valve with your hand, turn on the water cautiously to avoid splashing, and let it flush out the toilet valve for a few seconds.

Step 6: Replace the Washer

Upon removing the cap to flush out the valve, carefully inspect the washer for wear or cracks. If the washer is worn or cracked, replace it by prying the old washer out of the cap with a small screwdriver and pressing the new one into place. While replacing a damaged washer is cost-effective and straightforward, identifying the correct washer may pose a challenge. Common washers are typically available at home centers and hardware stores. It’s worth noting that professional plumbers often opt to replace the entire fill valve instead of searching for a specific washer.

Step 7: To Replace the Fill Valve, Start by Removing the Water from the Tank

- Turn off the water at the shutoff valve.

- Flush the toilet and hold the flush valve open to drain the tank.

- Sponge out the remaining water or vacuum it up with a wet/dry vacuum.

If you don’t have a shutoff valve, turn off the water supply at the main shutoff valve where water enters your home. This presents an opportune time to install a shutoff valve next to the toilet or replace a leaking one. It’s also an ideal moment to upgrade the supply line feeding your toilet.

Step 8: Remove the Coupling Nut

Unscrew the coupling nut that connects the supply line, ensuring that the toilet valve is held in place inside the tank to prevent it from turning. For added stability, use a locking pliers to secure the base of the toilet valve. It’s advisable to place a towel on the floor underneath to catch any water that may drain from the line.

Step 9: Remove the Old Flapper Valve

Remove the locknut securing the toilet valve to the tank. While unscrewing the nut, gently push down on the valve, then pull out the old valve.

Step 10: Measure the Overflow Tube

Measure the height of the overflow tube, taking the measurement to the top of the tube and not to any water level label on the tube.

Step 11: Twist the Top of the New Valve to Adjust the Height

Adjust the height of the new fill valve by holding the base and twisting the top. The distance from the base to the CL (critical level) mark should equal the height of the overflow tube plus one inch.

Step 12: Install the New Fill Valve

Remove the cap, press down to compress the washer, and screw on the locknut. Reconnect the supply line, flush the valve, and ensure there are no leaks. Finally, reset the cap in place.

Step 13: Cut the Fill Tube to Fit the Angle Adapter

Slide the fill tube onto the fill valve, attaching the angle adapter onto the overflow tube. Adjust the tube to the appropriate length, then affix it onto the angle adapter.

Step 14: Adjust the Float

Turn on the water to fill the toilet tank. Pinch the spring clip and slide the float up or down to set the water level one inch below the top of the overflow tube or align it with the water line marked on the tank. Once the water supply is restored, promptly check for leaks, tightening the nuts if needed.

Step 15: Fixing the Flush Valve – Identifying Issues

Begin by listening for running water after pushing down on the flapper with a yardstick. If the running water sound ceases, the flapper requires replacement. In cases where applying extra pressure on the flapper doesn’t resolve the issue, water may be escaping through a cracked or corroded overflow tube. In such instances, detaching the tank from the bowl and replacing the entire flush valve is necessary. Since problems with the overflow tube are uncommon in causing a running toilet, this repair will not be addressed here.

Step 16: Cleaning the Flapper

Turn off the water supply, flush the toilet to empty the tank, and run your finger around the flush valve seat rim. If mineral deposits are detected, use an abrasive sponge or Scotch-Brite pad to gently clean the flush valve seat. Avoid anything that might roughen it. If cleaning doesn’t resolve the issue, proceed to replace the flapper.

Step 17: Removing the Flapper

Detach the old flapper from the ears of the overflow tube and disconnect the chain from the handle arm.

Step 18: Installing the New Flapper

Attach the new flapper to the overflow tube and link the chain to the handle arm, leaving 1/2-in. of slack in the chain. Ensure the chain has enough slack to prevent tangling or hindering the flapper from closing firmly. Turn the water back on and test-flush the toilet. Note that flapper replacement steps may vary based on your specific type of flapper.

Step 19: Replacing a Broken or Corroded Toilet Flush Handle

Toilet flush handles, prone to loosening or corrosion, can cause ongoing running issues. Removal of the flush handle involves a trick: the retaining nut inside the tank is reverse-threaded. Stand in front of the toilet and turn the nut to the left to loosen it. Once loosened, remove the old handle and lever, insert the new handle, and secure it by threading on the retaining nut. Tighten by turning to the right.